Achieving IAQ Compliance at an East Coast High School

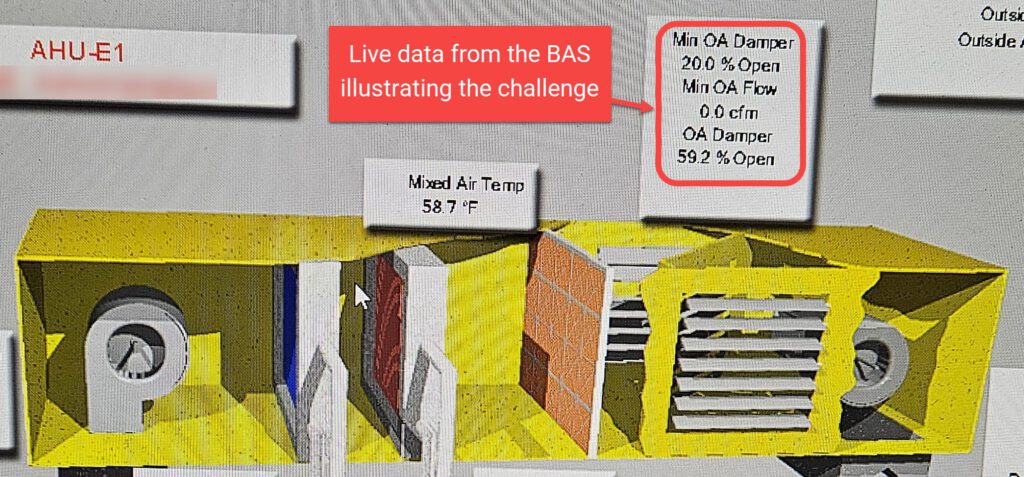

an AHU (air handling unit) at the east coast high school

one of the school’s RTUs (rooftop units)

Overview

A high school on the east coast needed a reliable solution to meet Connecticut’s IAQ (indoor air quality) mandate. Their existing OA (outdoor air) flow stations were faulty, making it difficult to ensure proper airflow and compliance with ASHRAE standards. By implementing TrueFit® AFMS, the school gained a complete, unified, system-level view of airflow within its HVAC units, providing accurate data with minimal maintenance requirements.

The Challenge

The school’s facilities team struggled with faulty OA flow stations, which failed to provide accurate airflow readings. Live data from the BAS (building automation system) showed that Minimum OA Flow was reading 0.0 cfm, even when outdoor air dampers were open.

Closer inspection revealed that the OA velocity sensors—located at the RTU’s outdoor air intake and exposed to unfiltered, unconditioned air—were corroded, causing inaccurate readings. These failures made it impossible to verify proper airflow and maintain compliance with ASHRAE fresh air change rate requirements.

The school needed a reliable, low-maintenance solution to accurately measure and control OA delivery.

The Solution

Trueflow Testing and Balancing LLC recommended the AFMS as a superior alternative to traditional OA flow measurement methods. This solution included:

- Velocity Probes Installed at the Supply Air Fan Inlet—Placed inside a controlled air space, eliminating corrosion risks and reducing maintenance needs to near zero while ensuring accurate airflow measurement.

- Differential Pressure Sensor on the Return Air Damper for Pressure Assist—Also installed in a controlled air space, further improving reliability and accuracy.

- Characterized Airflow Performance®—Uses a learning mode sequence to develop a damper characterization table that enables precise OA flow calculations without the need for direct OA velocity sensors.

By relocating key sensors to controlled environments, the AFMS eliminates the common failure points of traditional OA flow stations and ensures a long-term, low-maintenance solution for precise airflow measurement and IAQ compliance.

velocity probes installed at the supply air fan inlet

pressure assist sensor on the return air damper

the min/max OA damper assembly

the inclinometer (a tilt sensor) installed on the return air damper

How It Works

the AFMS controller, installed in a weatherproof enclosure

Rather than relying on direct velocity sensors at the OA intake, the AFMS determines outdoor airflow using Characterized Airflow Performance. During its learning mode sequence, the system:

- Moves the outdoor air damper through multiple positions, measuring the resulting airflow and temperature at each step.

- Uses ASHRAE Standard 111 mixed air equations to calculate the ratio of outdoor air to return air.

- Creates a damper characterization table, allowing the system to accurately determine OA flow based on damper position and system conditions—without the need for fragile OA velocity sensors.

This approach ensures accurate and repeatable outdoor airflow measurements, even in challenging equipment configurations where traditional sensors would fail.

Results

By installing the AFMS, the school immediately gained:

- Accurate Airflow Measurement—Ensuring compliance with ASHRAE fresh air change rate requirements.

- Minimal Maintenance—A long-term, low-maintenance solution for consistent airflow measurement.

- IAQ Compliance Assurance—The ability to track and document proper OA delivery.

- Trending & Reporting—Data-backed proof of diligence in maintaining IAQ standards.

Unlike traditional setups that rely on disparate sensors, which often produce readings that don’t balance with each other, the AFMS delivers a complete, system-level view of airflow within the HVAC unit.

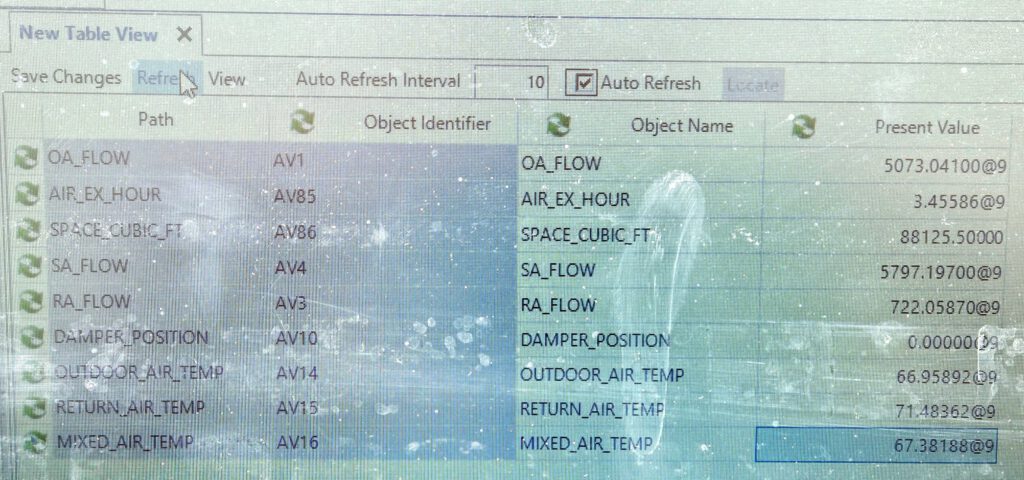

The installation now provides the school’s facility staff with a unified, accurate data set, including:

- Outdoor Air (OA) Flow

- Air Changes per Hour (AC/H)

- Supply Air Flow

- Return Air Flow

- Damper Position

- Outdoor Air Temperature

- Return Air Temperature

- Mixed Air Temperature

The AFMS installation now provides the school’s facility staff with a unified, accurate data set. (Dirt from working on the HVAC unit is on the field laptop screen shown.)

This holistic approach ensures that all airflow components are measured in relation to one another, giving facility staff a balanced and reliable view of HVAC unit performance. With these enhanced monitoring capabilities, they can now maintain optimal indoor air quality while eliminating the guesswork associated with conflicting sensor data.

Looking Ahead

With the success of the initial installation, the school is now evaluating the AFMS for the remainder of its ~40 RTUs to further expand its IAQ compliance efforts.

For more information about the TrueFit Airflow Measurement System, please visit the AFMS solutions page or contact the KMC Controls sales team.

The TrueFlow Testing & Balancing LLC logo is the trademark/service mark of its owner, used with permission after approval of this content.

Cart

Cart